29 January 2026

Manufacturing, logistics and automation firms today face increasing complexity. Equipment is more advanced, maintenance requirements more demanding, and the cost of unplanned downtime is steep.

Yet many organisations still rely on traditional documentation: PDFs, long manuals, static drawings and spreadsheets. This often leads to confusion, delays, maintenance errors and ultimately, increased downtime.

Over time, it becomes clear: the problem isn’t lack of effort, but lack of a documentation system that matches the reality of modern equipment and maintenance needs.

When documentation is fragmented or outdated:

These issues are common across industries. They slow down maintenance, create unnecessary risk, and reduce overall operational efficiency.

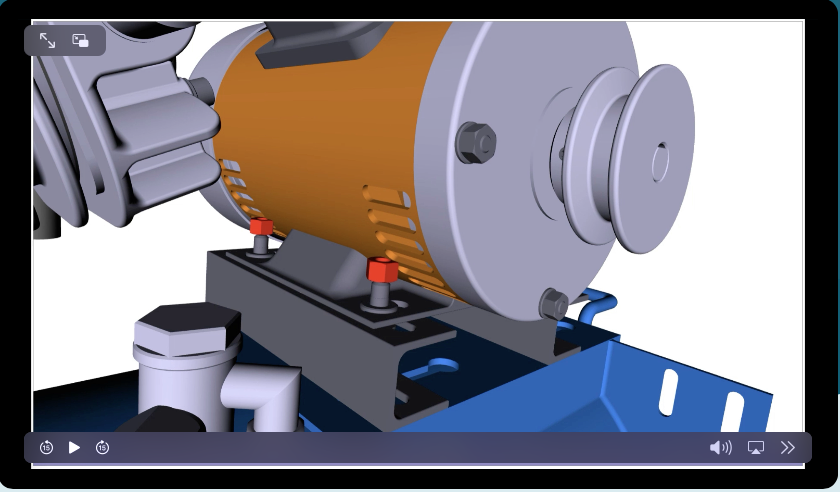

Invisu Altus, our new automated service, transforms how you handle documentation, maintenance, parts and training. By converting CAD data or existing documentation into interactive 3D visualisations — including digital versions of manuals, exploded-view parts catalogues, interactive maintenance and repair procedures, and optional 360° virtual walkthroughs — we give teams a more intuitive and reliable way to understand, maintain and operate complex equipment.

This is not just about prettied-up images. It’s about clear, accurate, accessible information - anytime, anywhere - designed for real-world industrial use.

When you use Invisu Altus, you get:

Before:

A maintenance technician receives a breakdown call. The manual is a 60-page PDF. The technician spends time hunting drawings, cross-referencing part numbers, and trying to visualise assemblies in their head. By the time they figure it out, downtime has already cost valuable production hours.

After using Invisu Altus:

The technician opens the relevant equipment’s Altus file on a tablet, selects the affected sub-assembly, sees exploded views, part names, hierarchical structures, and a step-by-step procedure. They order or locate the correct part instantly, follow the 3D instructions safely, and complete maintenance far quicker, reducing downtime and avoiding costly mistakes.

This service is ideal for:

What exactly do you need from us to get started?

We work from your existing CAD data or equipment drawings. From there, we create interactive 3D documentation, parts catalogues and maintenance procedures with no extra burden on your team.

Can this work alongside existing systems?

Yes; the service can complement or replace static documentation, integrating into your existing workflows to improve clarity and reduce reliance on paper or PDFs.

How quickly can we see value?

Once the 3D documentation is created, maintenance teams can start using it immediately so less time spent searching for instructions, clearer part identification, and fewer mistakes from day one.

Is it just for maintenance?

Not at all. It supports build, installation, commissioning, training, parts ordering — wherever clarity and accurate documentation matter.

In today’s fast-moving industrial world, traditional documentation isn’t enough. You need clarity, precision, and a system that keeps up with your equipment and your team.

With Invisu Altus you get a documentation system built for modern operations. Invisu Altus simplifies maintenance, improves safety, supports training, and saves time.

If you’d like to explore whether it’s right for your organisation, our team would be happy to talk or you can upload your documents to us today and we’ll get started:

https://invisu.uk/cad-to-interactive-3d/